Outsource Your Inbound Logistics Services For Growth

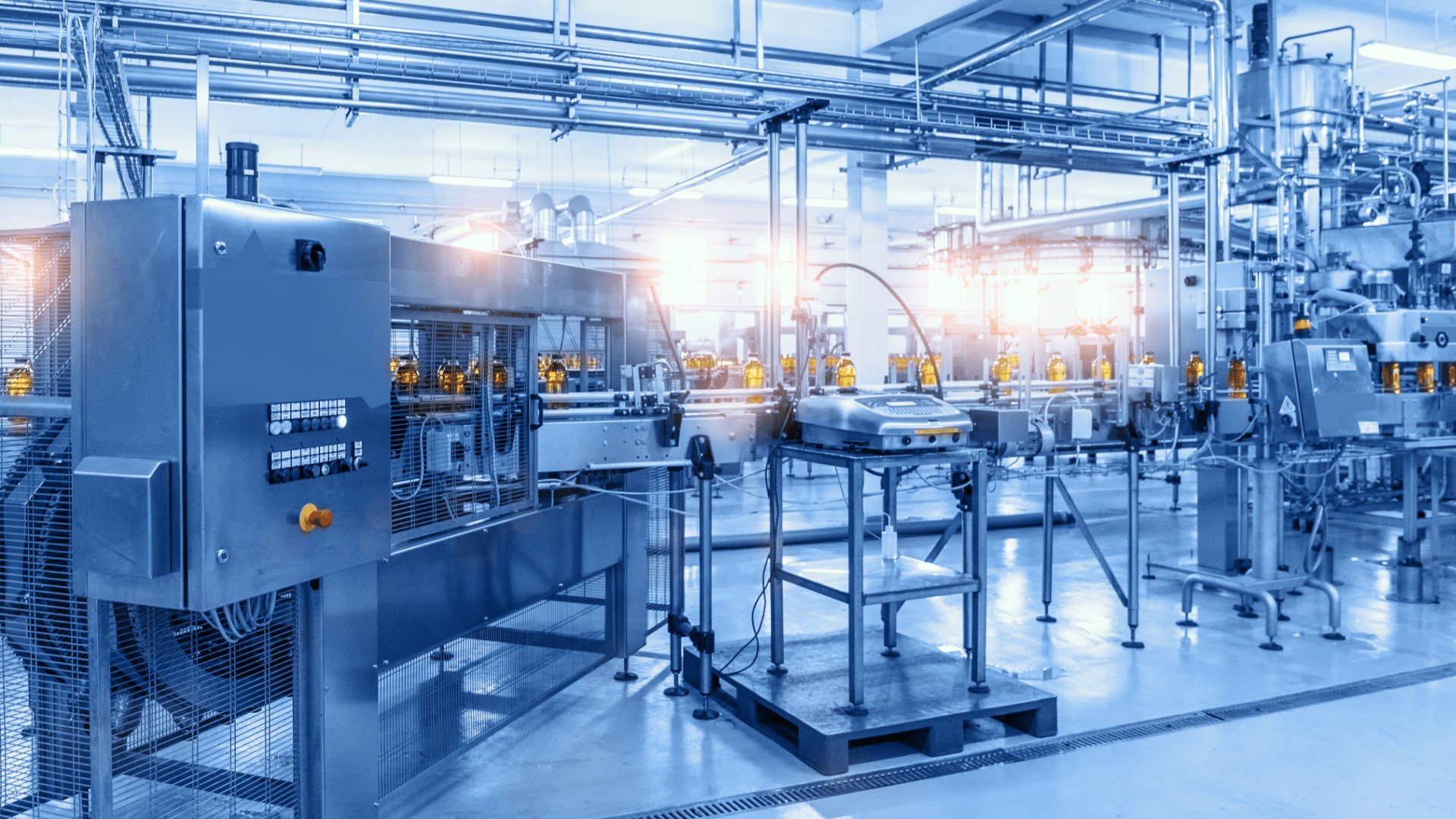

Outsourced inbound logistics services allow manufacturer to rack up savings.

Key Challenge

How could the company increase manufacturing capacity and provide support for storing raw and finished goods? With 900+ annual inbound shipments of raw materials and 150,000 sq. ft. in use for storage, the company needed to command the space to increase manufacturing. Furthermore, the company had to decide how to store and manage 1,700 annual outbound shipments of finished goods. While facing these challenges, the company also wanted to devote focus to its core competencies.

Solution

The client partnered with FIDELITONE to operate inbound logistics through a nearby warehouse and fulfillment services center. FIDELITONE began providing services to manage receipt of raw materials from vendors, conducting inspection and quality assurance of materials as they arrive. It implemented a process of shuttling materials to the production facility in rhythm with manufacturing requirements. In addition, the warehouse became the hub for receiving and storing finished goods. Applying expertise in complex B2B fulfillment, FIDELITONE began managing order fulfillment to the client’s customers.

Being only a few miles away, FIDELITONE’s warehouse and fulfillment center acts as a highly efficient extension of the client’s manufacturing operation. Removing the need for storage of both raw materials and finished goods opened up space for expanded manufacturing.

Support traceability

The Warehouse Management System implemented by FIDELITONE provides the ability to support inventory and fulfillment requirements, including FIFO, FEFO, expiration date, lot control, and more. Because the client is in a highly regulated industry, traceability is critical; it is fully supported through robust, integrated data systems.

Visible and versatile

Across the manufacturing industry, downtime can cost $260,000/hr. FIDELITONE’s integration capabilities allow data to be sent quickly and accurately to support tight production schedules and reduce production downtime by having the right products in the right place at the right time. The systems in place ensure full visibility to track critical products and shipments at every step in the supply chain. This outsourced solution provides crucial versatility to respond to peaks and valleys in demand for manufacturing and finished goods fulfillment.

Outcomes

Outsourcing non-core business activities to an expert who specializes in supply chain management has led to a high level of service with reduced costs. The client no longer has to invest resources in hiring, training, and managing warehouse staff. Timely, accurate order fulfillment is earning customer loyalty while reducing chargebacks. With new efficiencies in place, annual revenues have increased by $720,000. Next up: The company plans to replicate this solution in multiple locations.

Share this Case Study:

Download the full case study to learn more about how FIDELITONE solved these challenges and delivered these outcomes.

More Case Studies

-

Inventory Forecasting – Worth It’s Weight In Gold

Inventory Forecasting – Worth It’s Weight In Gold In-house service organization for national home improvement retailer improves first-time repair rate…

-

Repair Parts: Cycle Times For The 21st Century

Repair Parts: Cycle Times For The 21st Century National consumer electronics retailer improves fill rate to over 95% and saves…

-

Flawless Forecasting Predicts Supply Chain Success

Flawless Forecasting Predicts Supply Chain Success Forecasting tool helps copier manufacturer achieve over 99% inventory accuracy on parts. Key Challenge…

Are you ready to discuss how FIDELITONE can address your needs and solve your challenges?