Expert Tips: Improve Warehouse Efficiency & KPIs

From managing your warehouse KPIs to inventory management practices, applying 5S, and leveraging technologies, there are many steps you can take to improve warehouse efficiency. With continuous product movement—both inbound and outbound, efficiency speaks to every aspect of warehouse management.

Today’s climate of economic uncertainty poses additional business challenges to warehouse operators. Consider the labor shortage and the push for higher wages, along with other inflationary costs, and the cost of shipping parcels. All of these factors point to innovation around managing efficiency and the bottom line.

Examining the moving parts, warehouse organization, practices, processes, and tools can open up opportunities for improvement. The payoff? You can increase productivity, protect products, reduce costs, and optimize service. Here are expert warehouse management tips gleaned from our in-house experts.

1 – Define and set KPIs

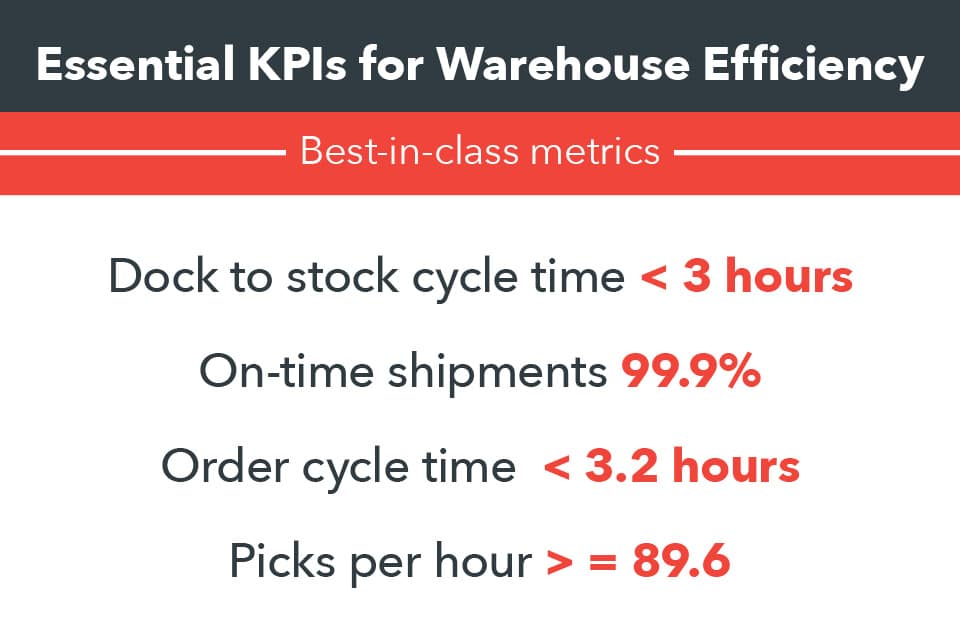

As Peter Drucker said, “You can’t improve what you don’t measure,” so defining KPIs is your first step. Define how you will measure your warehouse operation and set your goals for each. The most common and necessary KPIs are listed below. What are the best-in-class numbers for each?

2 – Use cycle counting and physical inventory

“Inventory has dollar value, so it’s very important that it is accurate,” explains Sonia Medrano, General Manager at the FIDELITONE Wauconda, IL warehouse in the blog, Inventory Cycle Counting: Best Practices to Ensure Accuracy.

Physical inventories should be conducted annually, at a minimum, as a best practice to ensure inventory accuracy. They provide a snapshot in time of your inventory so you can identify any discrepancies and remediate errors before the issue becomes more severe.

Cycle counting should be an ongoing practice to ensure inventory accuracy. With regular cycle counting, physical inventories are much less effort and may even be able to be forgone based on the results of cycle counts. Medrano advises establishing SOPs for cycle counting that include defined roles and responsibilities as well as processes, safeguards, and controls with corrective actions.

To manage cycle counting:

- Categorize your SKUs into groups based on velocity (e.g., groups A, B, C)

- The A category should be counted every 30 days, B every 60 days and C every 90 days. Plan for counting approximately 20% of SKUs in each category.

Ensuring inventory accuracy through physical inventories and cycle counting can head off disruptive surprises, while keeping financial reporting accurate.

3 – Optimize dock to stock processes

Spending time searching for a misplaced product during put-away is a huge drain on efficiency. Moving products from the receiving dock to stock locations accurately and quickly minimizes the risk of misplaced product and is the basis for being able to pick orders correctly. This depends on having effective processes and systems for put-away. Dock-to-stock should be no longer than 24 hours (ideally within a few hours of receipt) into locations identified by your warehouse management system.

4 – Focus on warehouse organization & 5S

Efficiency can’t be achieved without having an organized warehouse. When it comes to organization, the smallest of details matter. From placement of MHE to garbage cans, every detail adds up to achieving efficiency.

Implementing a 5S program and enforcing adherence to the program is critical. “5S is defined as a methodology that results in a workplace that is clean, uncluttered, safe, and well organized to help reduce waste and optimize productivity,” explains the American Society for Quality.

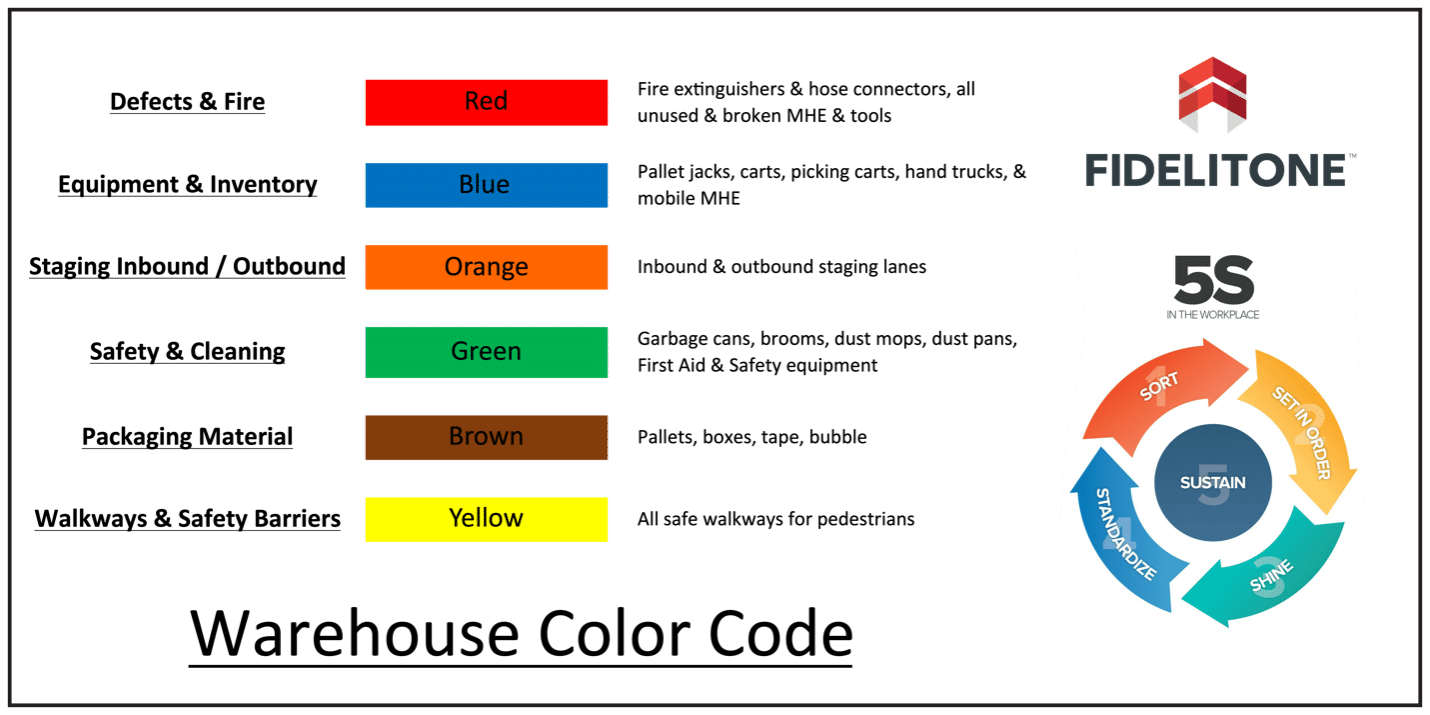

The components of 5S are: sort, set in order, shine, standardize, and sustain. Throughout the FIDELITONE network of warehouses, we use standardized color coding to help with warehouse organization. In accordance with the 5S system, warehouse organization places items where they need to be based on function, logical locations, and functional needs.

5 – Examine warehouse layout and space utilization

It’s no secret that filling up available space in a warehouse helps achieve profitability for your company, but what is “full”? The best practice is that your warehouse should be filled to 90% capacity. Allowing space for staff and equipment to maneuver and processes to be followed is necessary. You can’t maneuver or follow processes when there is no space to do so. Actually, being too full can reduce your efficiency and service performance. Devise a warehouse plan and layout to achieve 90% warehouse utilization, and you’ll achieve profitability goals as well as efficiency goals.

Designing the right layout of your warehouse is a critical part to improving efficiency. Consider: What type of racking do you need? How much? Where should it be placed? Are you allowing enough room for receiving, prep and staging? Proper layout can reduce bottlenecks, which will create efficiency. There are a lot of factors that go into warehouse layout. It is a combined effort among operations, engineering, and IT infrastructure teams.

6 – Implement Continuous Improvement

If you aren’t continually looking for ways to improve, there’s no doubt you are sacrificing efficiency. Continuous improvement is an ongoing, organized way to perfect what you do and how you do it. Having a team and process in place for evaluating opportunities for improvement within the warehouse is one of the most basic yet important tactics for achieving efficiency.

One of the first things that should be on your continuous improvement plan is an ongoing slotting analysis. Slotting means organizing SKUs based on characteristics such as velocity, size, product type, or other characteristics. Having the right SKUs in the right place results in efficient picking. “Slotting analysis should be done on a regular basis in conjunction with warehouse design and layout, replenishment processes, and velocity data,” explains Keegan Hill, Regional Manager of operations at FIDELITONE. “Slotting is a data-driven analysis turned into physical form.”

7 – Use technology as a power tool

Simply put, efficiency can’t be achieved without the right technology. Think of technology as your power tool that helps you achieve more with less and empowers you to do what otherwise might not be possible.

Going back to the KPIs you defined, consider how to measure them effectively. You can leverage your WMS or business intelligence tools to track and report on KPIs. This helps you determine the health of your operation and define and tackle any weak spots.

Your WMS must also be able to support efficient picking and packing processes. Your warehouse layout, processes, and WMS will all work together to achieve efficiency in the warehouse.

8 – Invest in MHE & warehouse automation

Alongside your technology, warehouse automation is one of the rapidly growing ways of achieving warehouse efficiency. Automated conveyor systems? Pick to light? Voice directed picking? Robots? Each brings their own value and benefits. An estimated 4 out of 5 warehouses have no automation today. However, “Industry experts expect to see an increase in adoption over the next 5 years, driven by several trends, including an ongoing labor shortage, a more integrated warehouse and the introduction of better and more affordable solutions,” reports Supply & Demand Chain Executive.

Selecting the right automation for your products and business can be one of the most impactful ways to gain efficiency. The costs (upfront and ongoing) can be significant, but so can the benefits. It pays to invest in what you need to operate efficiently, minimize impact of labor challenges, and mitigate rising labor costs.

9 – Conduct training, training, and more training

Whether it is a process, technology, method, or business practice, you can never have enough training. Initial and ongoing training of staff is essential as staff members are the ones who execute. If they aren’t following a defined process or using your technology correctly, everything you put in place goes to waste.

The solution? Create a training plan and bring in the resources needed to provide effective and ongoing training. It’s an investment that pays off in aligning all activity around defined processes, moving towards common goals. What’s more, it drives efficiencies and promotes employee retention.

Keep in mind that having the right operational leadership in your building is essential for proper training. Think carefully about the roles and ratios you need. A quick ratio guideline is one manager for every 10 employees. This gives each employee access to the proper training and attention they need to be successful.

To improve warehouse efficiency, think of a Rubik’s cube—a complex puzzle in which the whole is affected by every small movement. By examining the nine areas above, you can make adjustments that deliver a stronger bottom line. To speak with a FIDELITONE expert about your warehouse management challenges, get in touch.

FIDELITONE helps you earn customers’ loyalty through specialized services in inbound logistics, order fulfillment, last mile delivery and service parts management.